With a turnover of nearly 100 million euros and over 400 employees, Voigt Logistik is among the leading transport and logistics service providers in Northern Germany.

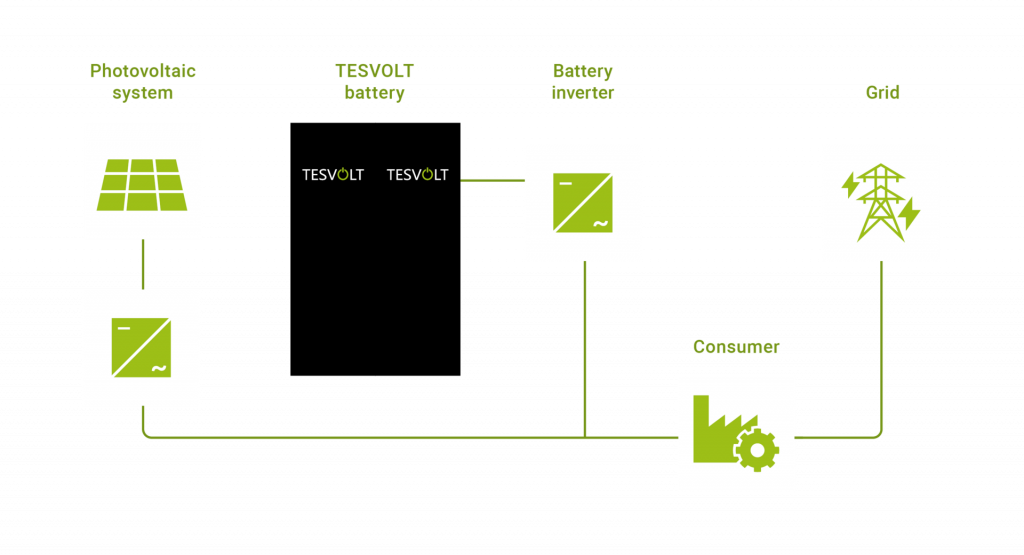

Due to this economic success, the company’s old handling centre’s capacity of 1,400–1,800 shipments a day had reached its limits. In Neumünster-Süd, the southern part of Neumünster, the company has thus established a new location with a 10,000 sqm large handling hall complete with 106 loading bays— an investment worth 15 million euros. This includes a 251 kWp photovoltaic installation, which Voigt Logistik had installed on the roof of the hall.

The work in a handling hall typically begins very early in the morning, often before sunrise, so electricity is needed to power the lights and air conditioning. The electric vehicles used for transporting pallets are in constant motion all day and cannot be charged until the evening, when most shifts end. An industrial battery storage system is the best solution for such a situation. Not only does it help to distribute the self-produced electrical energy throughout the day, it also serves to cushion the peak loads that become necessary for charging the electric vehicles.

The requirements for a storage solution:

- Easy upgrading by way of an expandable system

- Great durability to safeguard operation and investment long-term

- Sufficiently high performance for capping peak loads when e-vehicles are charging

German

German Italian

Italian Dutch

Dutch

by

by